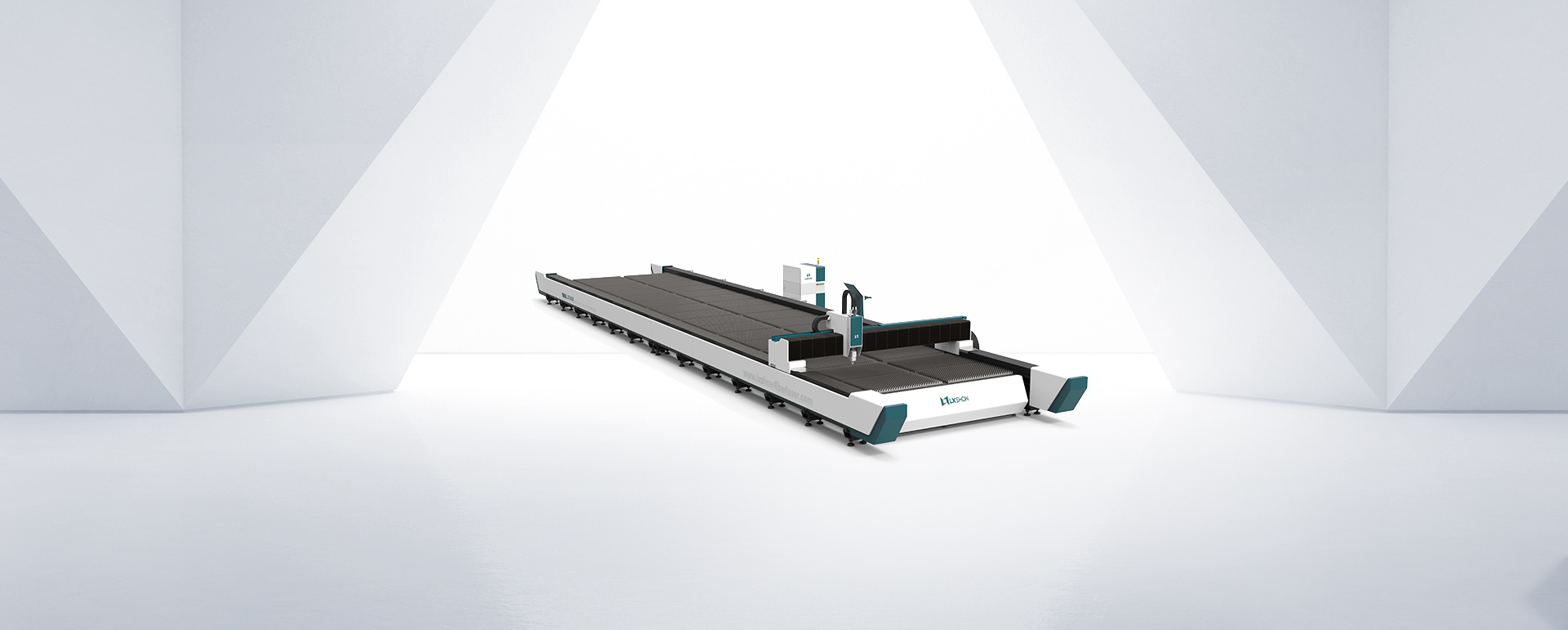

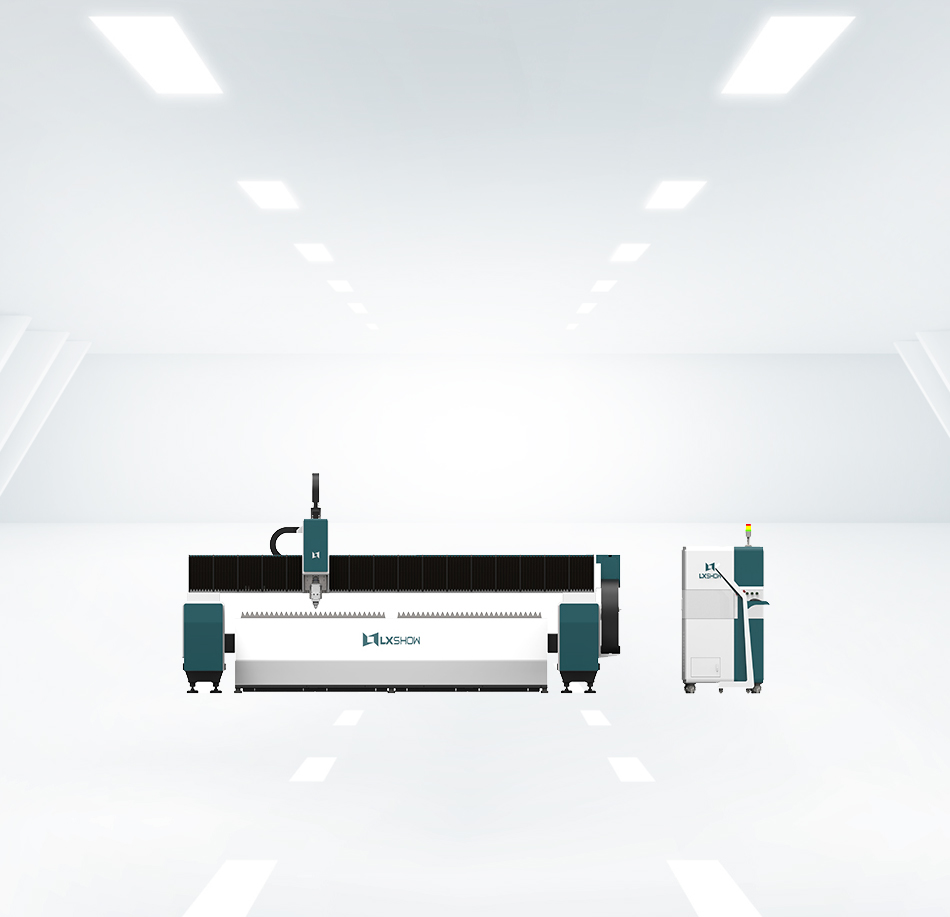

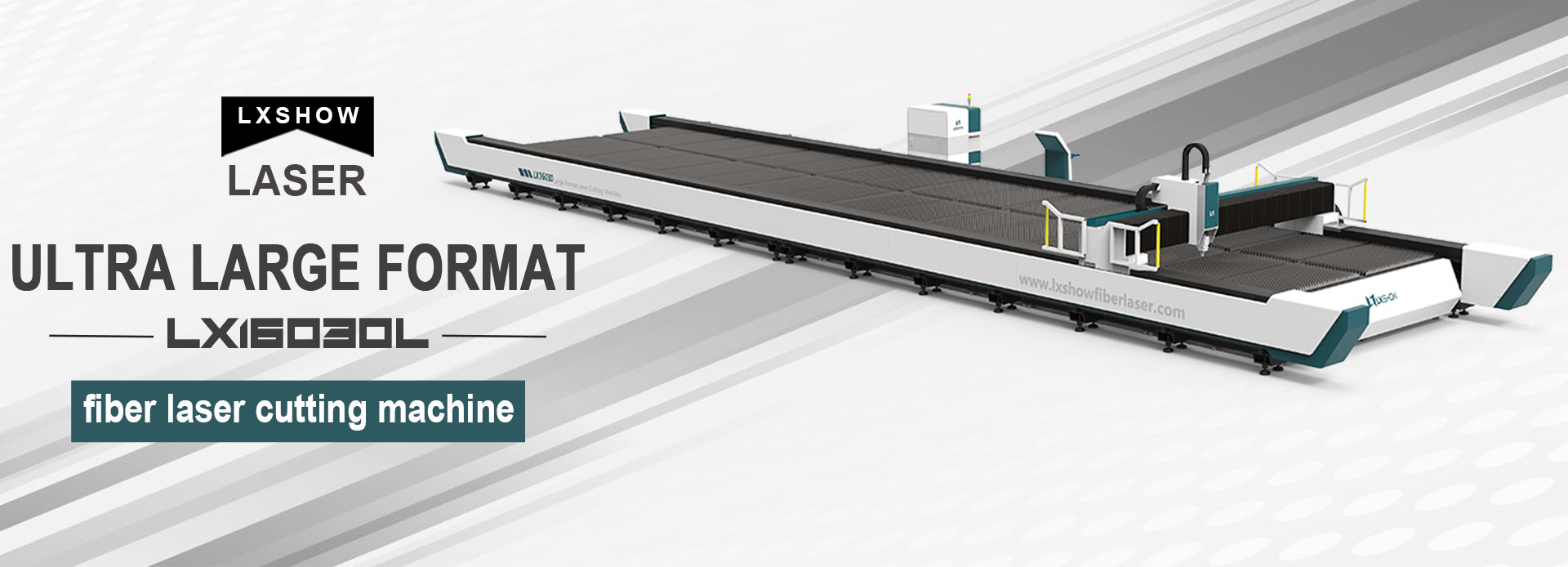

Maximum cutting area could be 24500mm*3200mm depend on your working , power up to 20000W

Innovative environmental protection ventilation system :The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly

A safety grating is installed on the beam. When a person enters the processing area by mistake, the equipment will brake immediately, effectively avoiding dangerous situations.

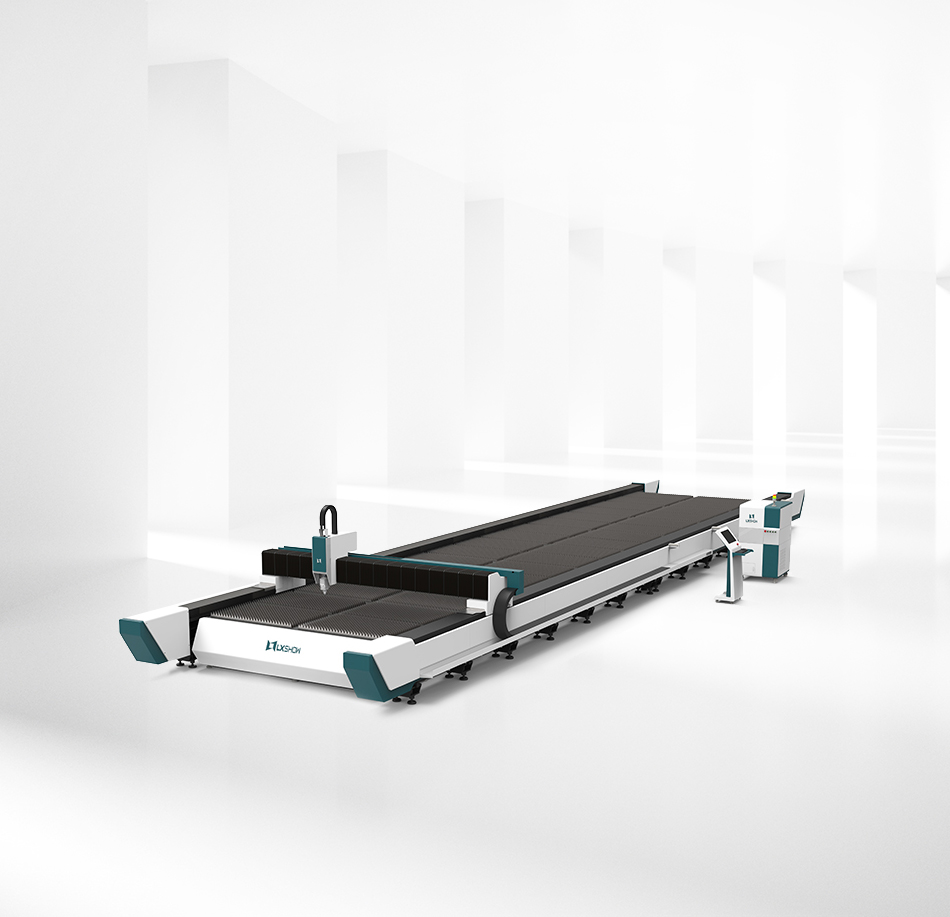

CUSTOMIZE THE PROCESSING FORMAT AT WILL

LXSHOW provides the flexibility to deal with ultra-large-format thick plates, segmented splicing bed, and the format can be customized on demand.

The separate design of the bed and worktable ensures the high dynamic performance of the machine tool and the service life of the machine tool. It can adapt to workpieces up to 3200mm wide and 50mm thick.

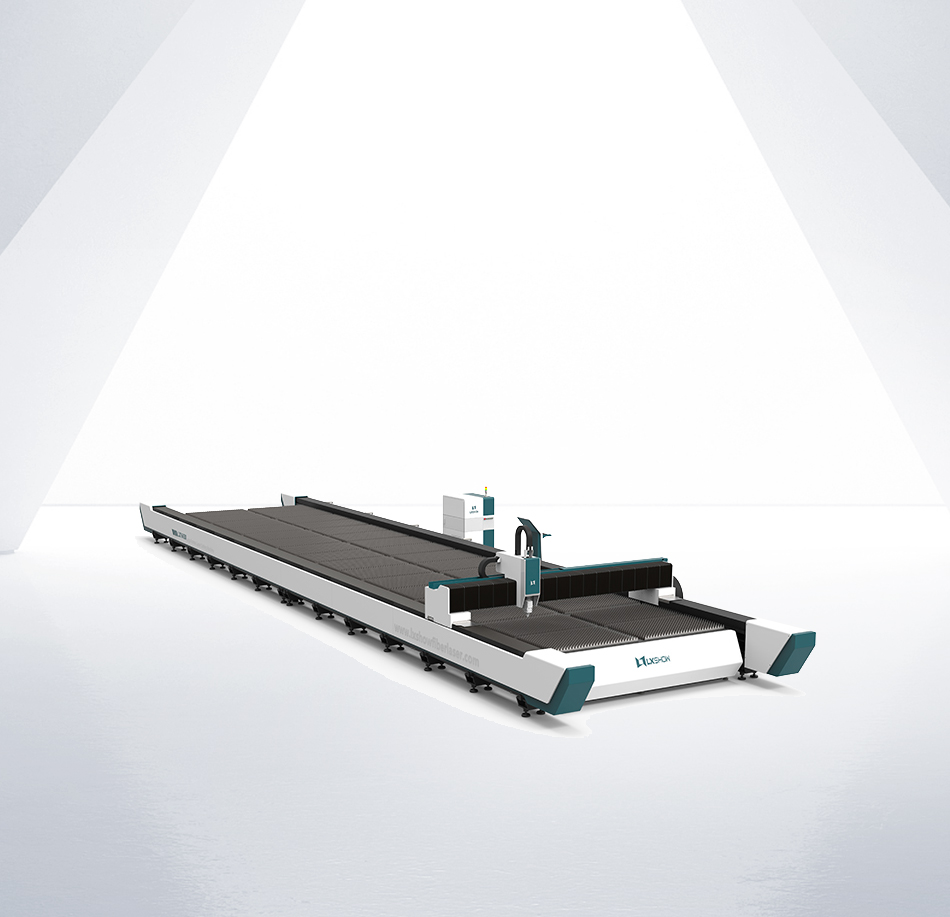

Segmented modular workbench, convenient and cost-saving for slag removal

Independent research and development of patented modular workbench, easy to disassemble and replace, without hindering production

Optional drawers, convenient for small parts cleaning, efficient, time-saving and safe maintenance.

ACTIVE SAFETY BRAKE

A safety grating is installed on the beam. When a person enters the processing area by mistake, the equipment will brake immediately, effectively avoiding dangerous situations.

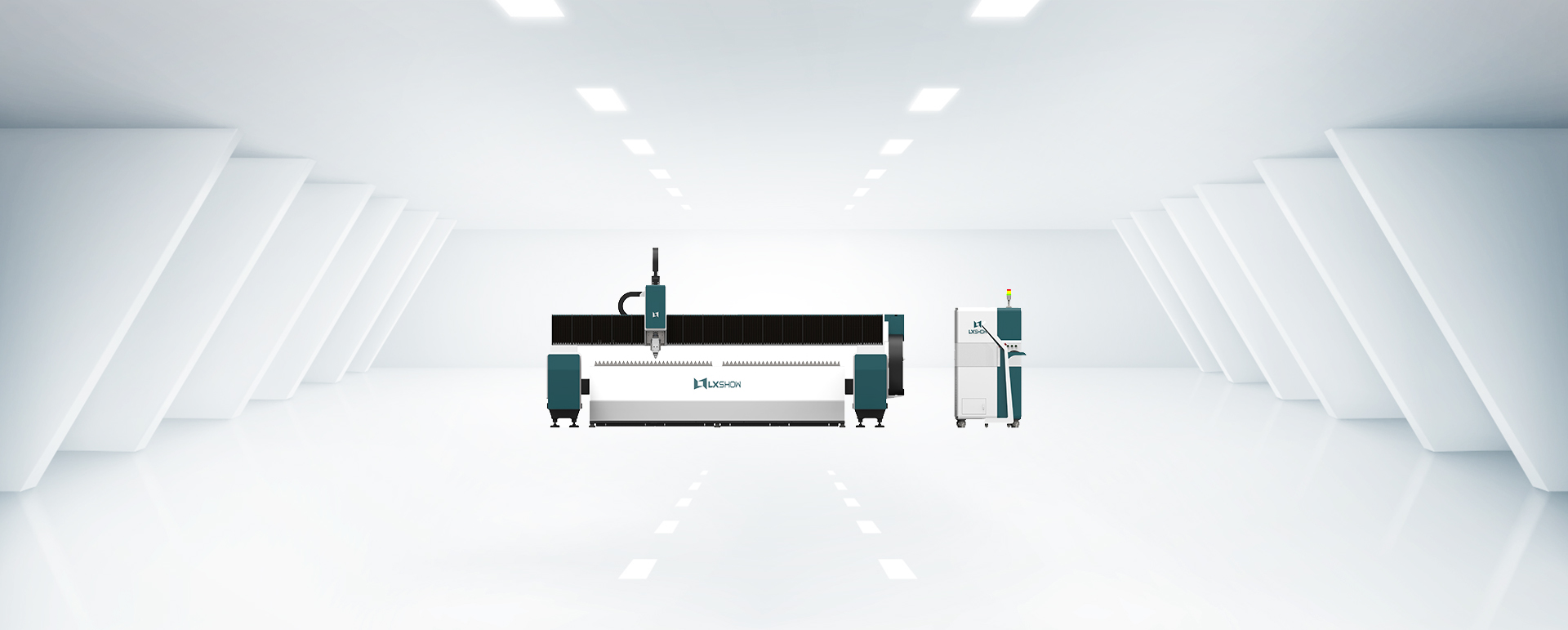

BOCHU SYSTEM

Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.

●New man-machine interaction pattern

●Flexible/batch processingmode

●Uitra-high-speed scanning & ctting with micro-connection

●Real-ime monitoring of core components

●Active reminder of machine maintenance

●Bult-in nesting software, save labor force

AUTO FOCUS CUTTING HEAD PRECITEC

• motorized focus position adjustment for automatic machine setup and piercing work

• lightweight and slim design created for fast acceleration and cutting speed

• drift-free, fast-reacting distance measurement

• permanent protective window monitoring

• automated piercing with PierceTec

• water cooling of the sheet metal with CoolTec

• completely dustproof beam path with protective windows

• LED operating status display

• output of all sensor data via WLAN to APP and machine control possible

• pressure monitoring in the nozzle area (gas cutting) and in the head

Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.

GENERATOR USING LIFE

The generator's using life (theoretical value) is 10,00000 hours. This means that if you use it for 8 hours a day, it can be used for about 33 years.

Generator Brand: JPT/Raycus/IPG/MAX/Nlight

INNOVATIVE ENVIRONMENTAL PROTECTION VENTILATION SYSTEM

Partition dust removal can instantly remove the smoke and dust generated by cutting, creating a clean and clean working environment for you.

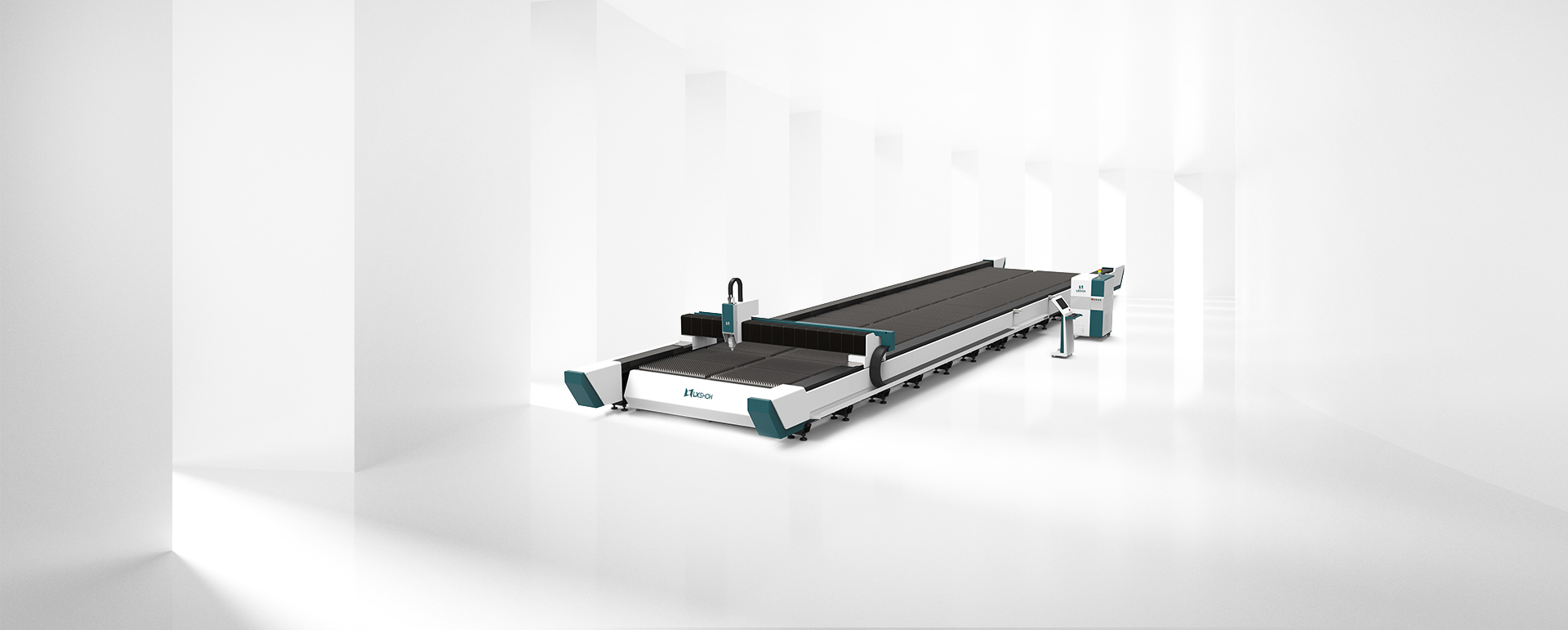

TRANSMISSION AND PRECISION

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

| Machine Model | LX12025L | LX12020L | LX16030L | LX20030L | LX24030L |

| Working Area | 12100*2550 | 12100*2050 | 16500*3200 | 20500*3200 | 24500*3200 |

| power of Generator | 4kw-20kw | ||||

| X/Y-axis Positioning Accuracy | 0.02mm/m | ||||

| X/Y-axis Repositioning Accuracy | 0.01mm/m

|

||||

| X/Y-axis Max. linkage speed | 80m/min | ||||

16030L 3kw 4kw 6kw 8kw fiber laser cutting machine Application

Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.