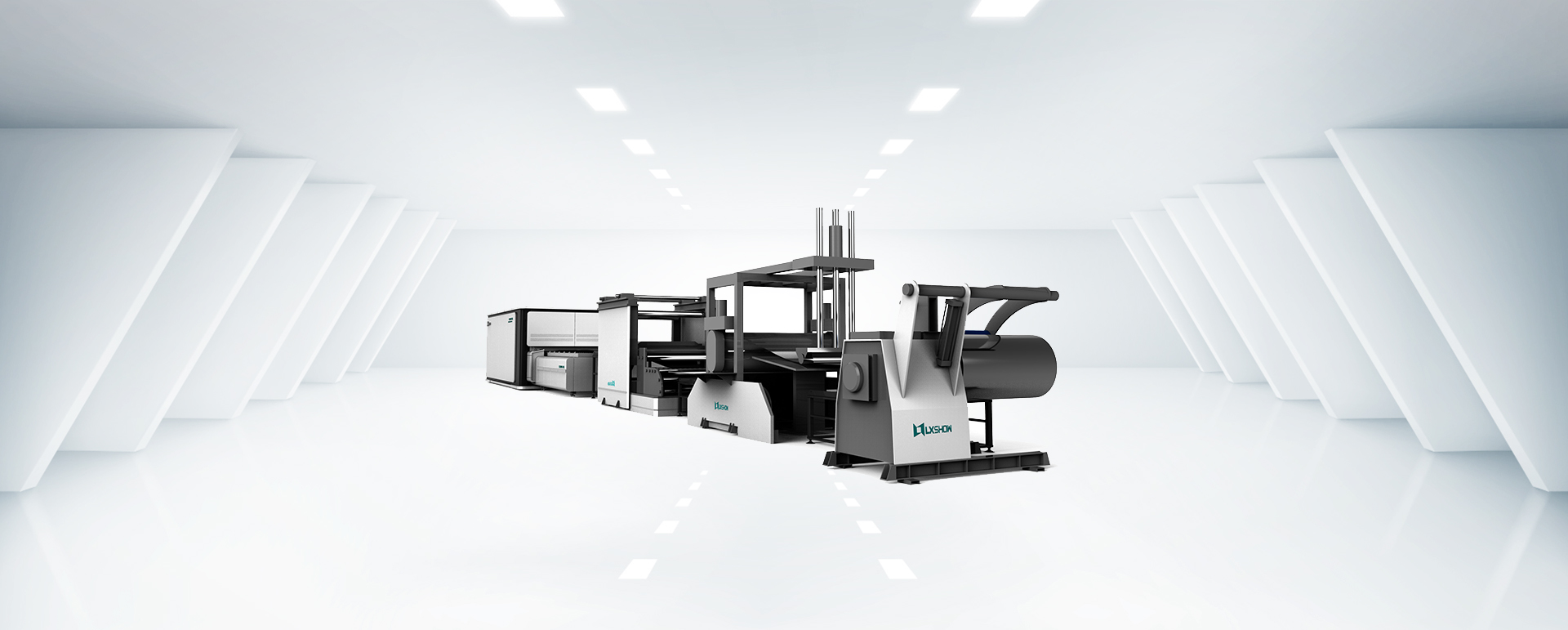

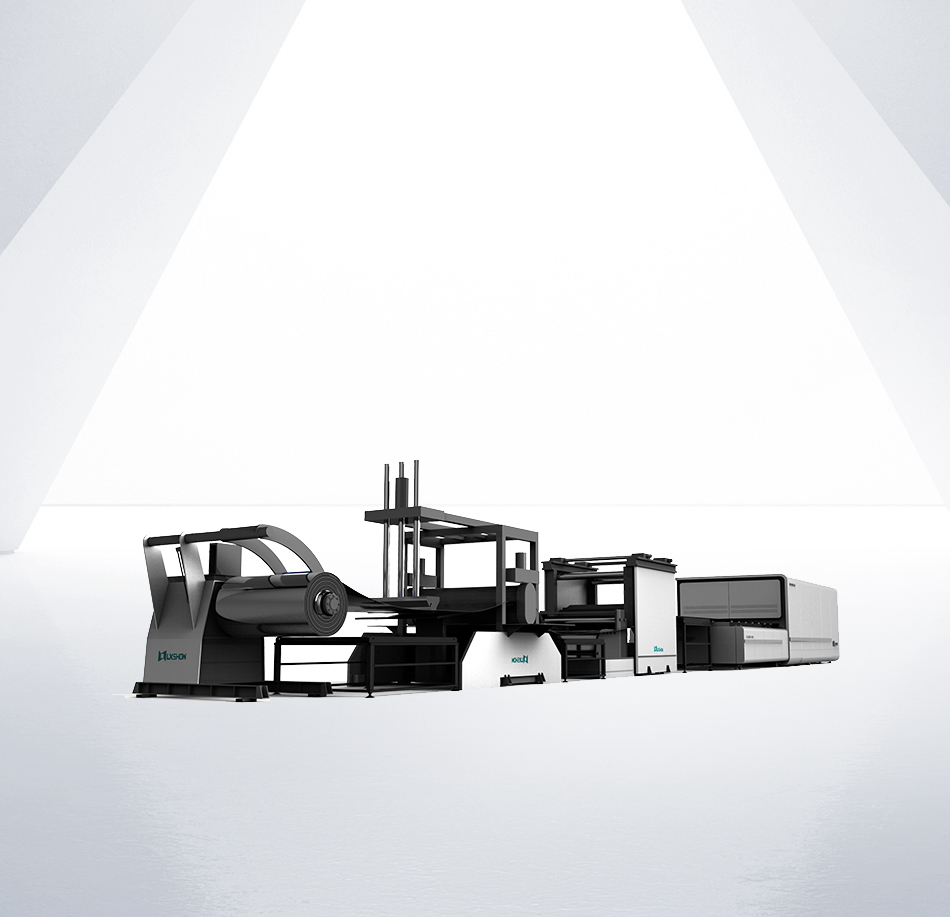

SOLUTIONS FOR A WHOLE PROCESSING SYSTEM

Coil cutting machine features with integration of automatic uncoiling, leveling, feeding and cutting to ensure the continuity of processing and production, improving processing efficiency. Flow line production and batch processing reduce labor intensity and save manpower. Full enclosure design with compact structure, higher safety and environmental protection during operation; flexible processing and application.

PROCESSING PARTS RANGE

Coil outer diameter:Φ1200-Φ2000mm

Coil inner diamete:Φ508 Φ610mm

Dimensions:3000mm*1500mm

Automatic feeding of coil material, continuous cutting and batch

processing improve processing efficiency and reduce labor intensity

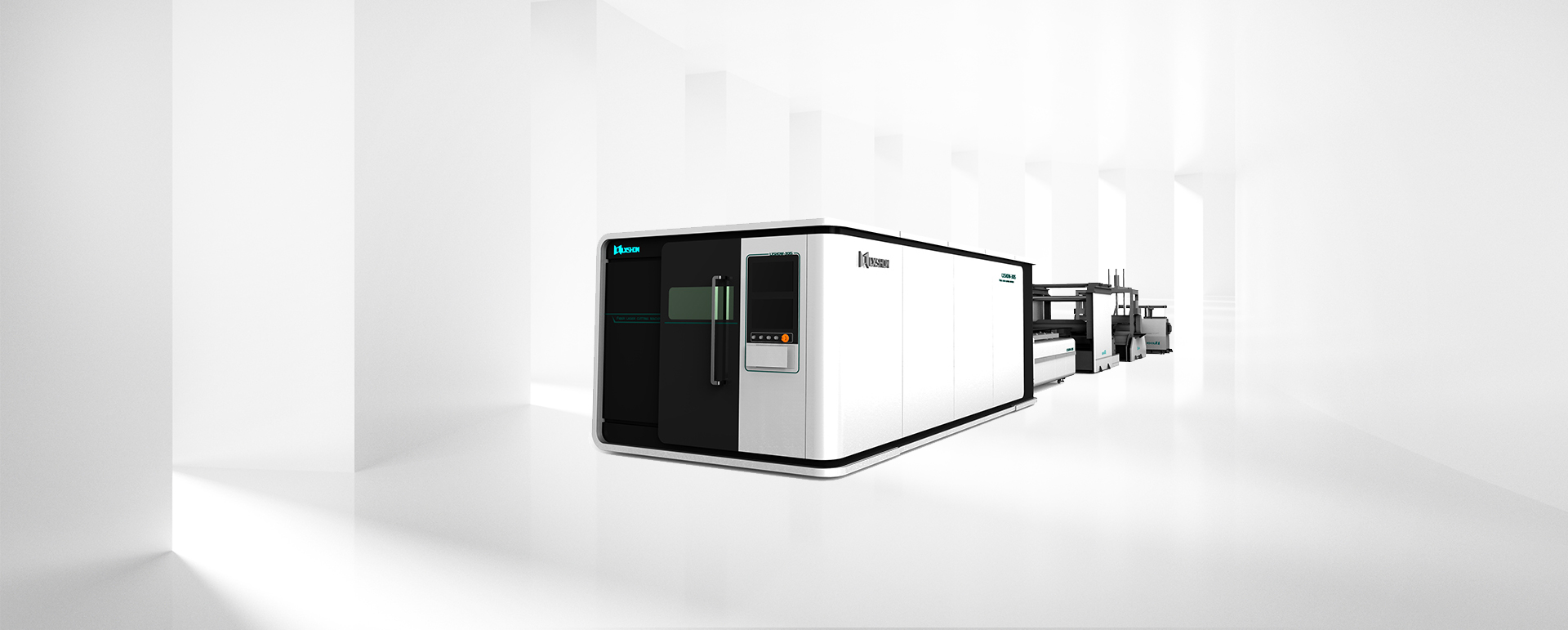

FULL PROTECTION COVER

Full closed protection improves using security; laser protection glass isolates laser radiation to human beings; automatic collection system of smokes and dusts is environment friendly; intelligent monitoring system reduces accident rate, making us enjoy beauty and health in cutting process.

UNCOILING PARTS

The uncoiler unwinds the roll material, and the width of the loaded coil material is 600-1250mm; the load is 10000kg.

LEVELING PARTS

leveling feeder leveling the material, adjustment accuracy of correction amount: ±0.01mm

AUTOMATIC UNLOADING, INTELLIGENT PALLETIZING

Adopt belt conveyor and adjustable width limiting device; the sheet material after processing is automatically transmitted to the unloading mechanism and then palletized by lifting mechanism according to the material width. Finished materials need no manual sorting any more, centralized sorting improves the working efficiency and saves labor cost.

ENVIRONMENT FRIENDLY AND HEALTHY

Full closed protection improves using security; laser protection glass isolates laser radiation to human beings; automatic collection system of smokes and dusts is environment friendly; intelligent monitoring system reduces accident rate, making us enjoy beauty and health in cutting process.

CAST ALUMINUM CROSSBEAM

After artificial aging, solution treatment and finishing, crossbeam owns good integrity, rigidity, surface quality, toughness and ductility. Aluminum alloy’s metal characteristics of light weight and strong rigidity are helpful to high speed movement in processing, and high flexibility is beneficial to high-speed cutting of various graphics based on high accuracy. Light crossbeam can give equipment a high operation speed, improving processing efficiency to ensure processing quality.

AUTOMATIC UNLOADING MATERIAL

Hobbing type conveying structure,vacuum chuck automatic unloading the unloading the finish product,automatic stacking of finished products,saving labor and improving efficiency.

Model Number: LX3015FL

Lead time: 15-35 working days

Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C.

Machine Size: (About)(5480+8034)*4850*(2650+300)mm

Machine weight: 10000KG

Brand: LXSHOW

Warranty: 3 years

Shipping: By sea/By land

| Machine Model | LX12025L | LX12020L | LX16030L | LX20030L | LX24030L |

| Working Area | 12100*2550 | 12100*2050 | 16500*3200 | 20500*3200 | 24500*3200 |

| power of Generator | 4kw-20kw | ||||

| X/Y-axis Positioning Accuracy | 0.02mm/m | ||||

| X/Y-axis Repositioning Accuracy | 0.01mm/m

|

||||

| X/Y-axis Max. linkage speed | 80m/min | ||||

LX3015FL aluminum stainless steel cnc optic metal sheet fiber laser cutting machine Application

Application Materials

Fiber Laser Metal Cutting Machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.