THE SEGMENTED RECTANGLE LASER TUBE WELDED BED

Good rigidity, high precision, no deformation during the life cycle;

Welded aluminum collet board, formed through high precision process. Good weight and good dynamic performance

BOCHU SYSTEM

Easyto operate evenby green hands, Match with 20000 process data on its graphical programming interface, Compatible with multile graphic files, incl. DXF DWG, PLT and NC code, Improve stock layout and material utilization by 20% and 9.5% by its built-in nesting software, with no limit of quantity of spare parts, Support language: English, Spanish, Portuguese, Russian, German, French, Italian, Japanese, Korean, Dutch, Czech, Simplified Chinese, traditional Chinese.

●New man-machine interaction pattern

●Flexible/batch processingmode

●Uitra-high-speed scanning & ctting with micro-connection

●Real-ime monitoring of core components

●Active reminder of machine maintenance

●Bult-in nesting software, save labor force

INTELLIGENT AUTOFOCUS

Stainless steel material, with water cooling function, dual cooling nozzles, ceramic ring, dual focus protection mirror, drawer type pluggable protection mirror, focusing collimator mirror, long service life.

Autofocus accuracy ±0.01mm. Good flow control for mirror surface cutting with less gas consumption. SS protective tube prevents sparks and burns.

Tips: The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.

GENERATOR USING LIFE

The generator's using life (theoretical value) is 10,00000 hours. This means that if you use it for 8 hours a day, it can be used for about 33 years.

Generator Brand: JPT/Raycus/IPG/MAX/Nlight

PNEUMATIC CHUCK

CLAMPING DESIGN

Automatic centering, with less waiting time for loading and unloading,3 times faster than electric chucks, Large and constant clamping force, keeping heavy tubes stable

PROFESSIONAL CLAMP DESIGN

Automatic pneumatic chuck, adjustable and stable, clamping range is wider and clamping force is larger. Non - destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.

FRACTIONAL AUTOMATIC SUPPORT INSTALLATION

The intelligent support frame supports chucks with high cutting accuracy and long service life, which prevents deformation during the cutting of long tubes.

INTELLIGENT ALARM SYSTEM

It can detect anomalies in advance, reduce hidden dangers, and double the effect of abnormal detection of equipment

Stroke intelligent protection

Detect whole process of cutting head working, quickly feedback the risk and stop it. Double protection with fixed limit to improve equipment and personal safety and reduce risk

ABSOLUTE SERVO MOTOR

The system has its own servo motor, which can work when it is turned on. When the power is cut off, the cutting operation can be resumed by pressing the button.

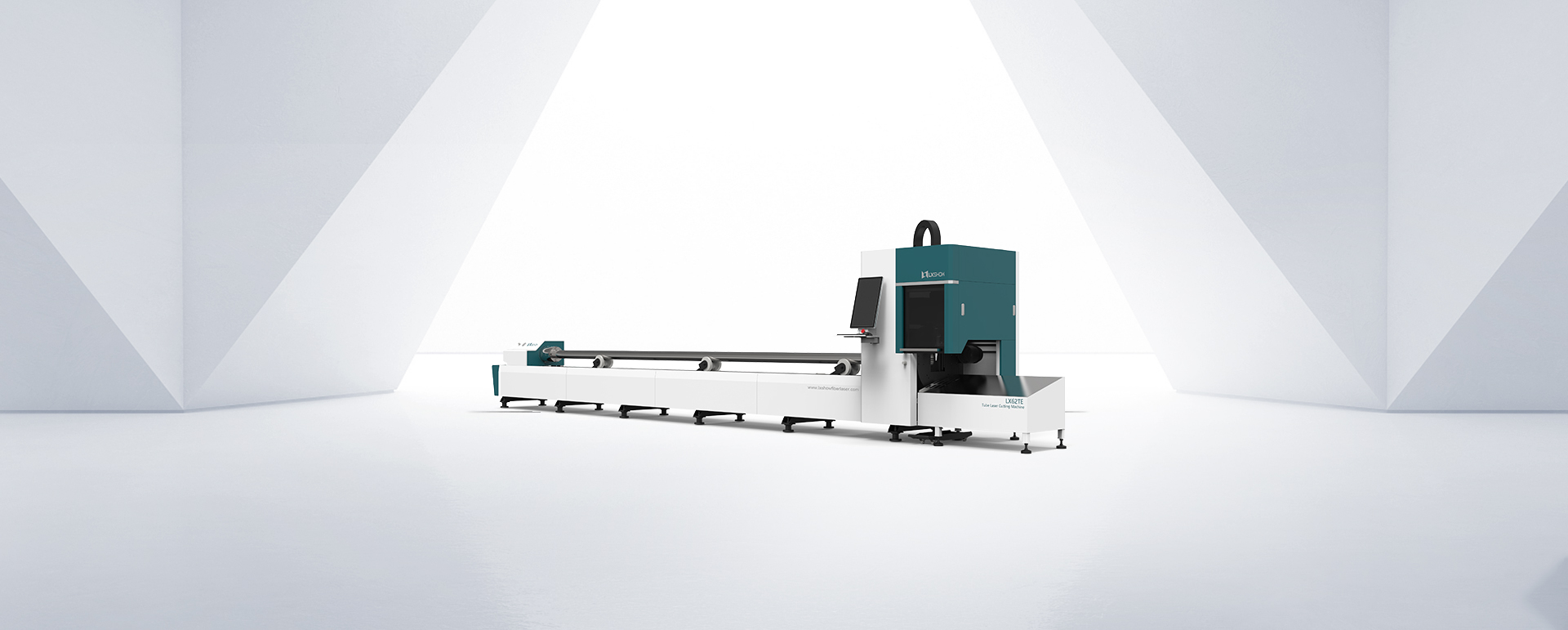

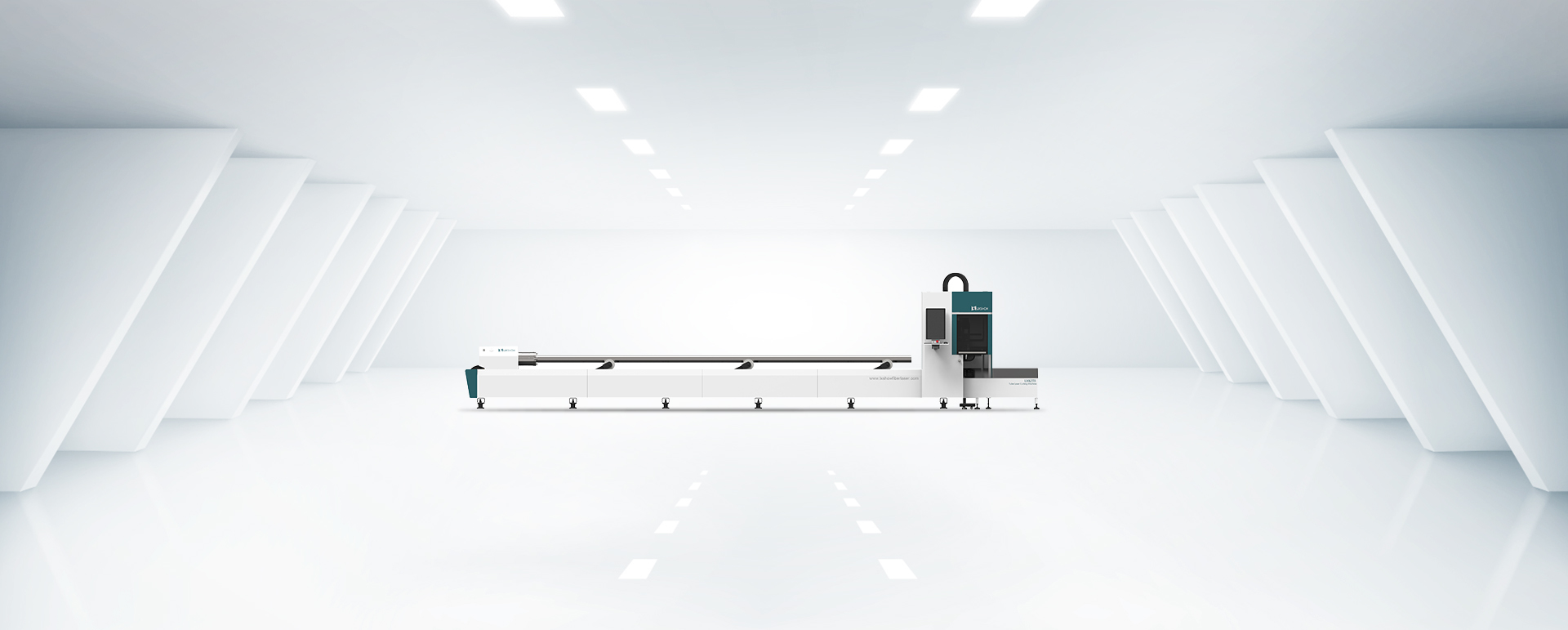

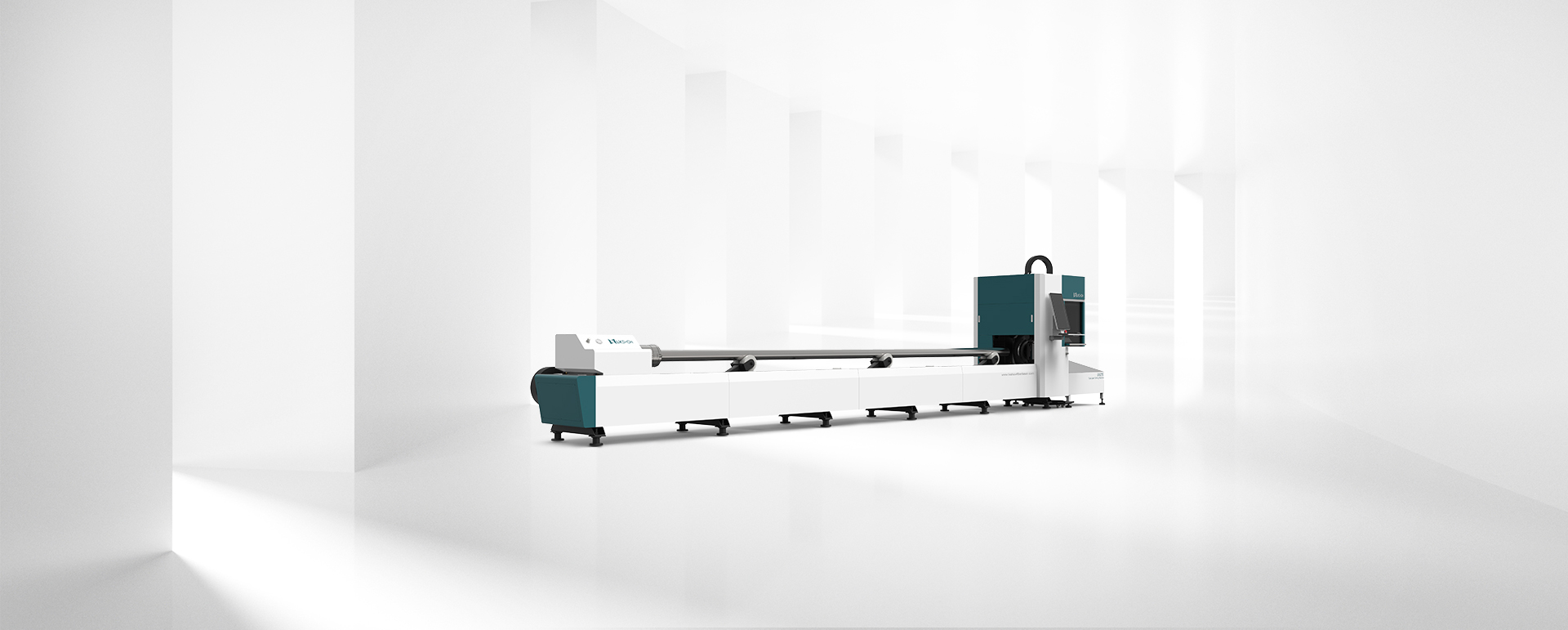

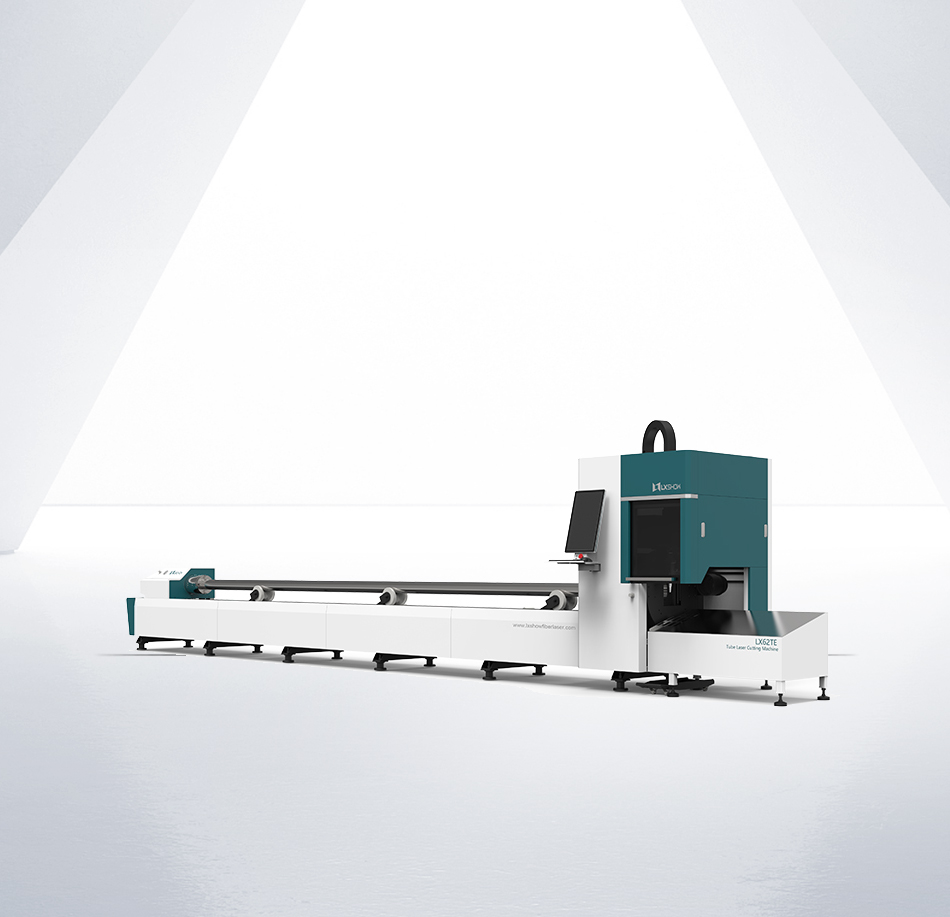

Model Number: LX62TE

Lead time: 10-25 working days

Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C.

Machine Size: 9340*1560*1615mm (About)

Machine weight: 8000KG(About)

Brand: LXSHOW

Warranty: 3 years

Shipping: By sea/By land

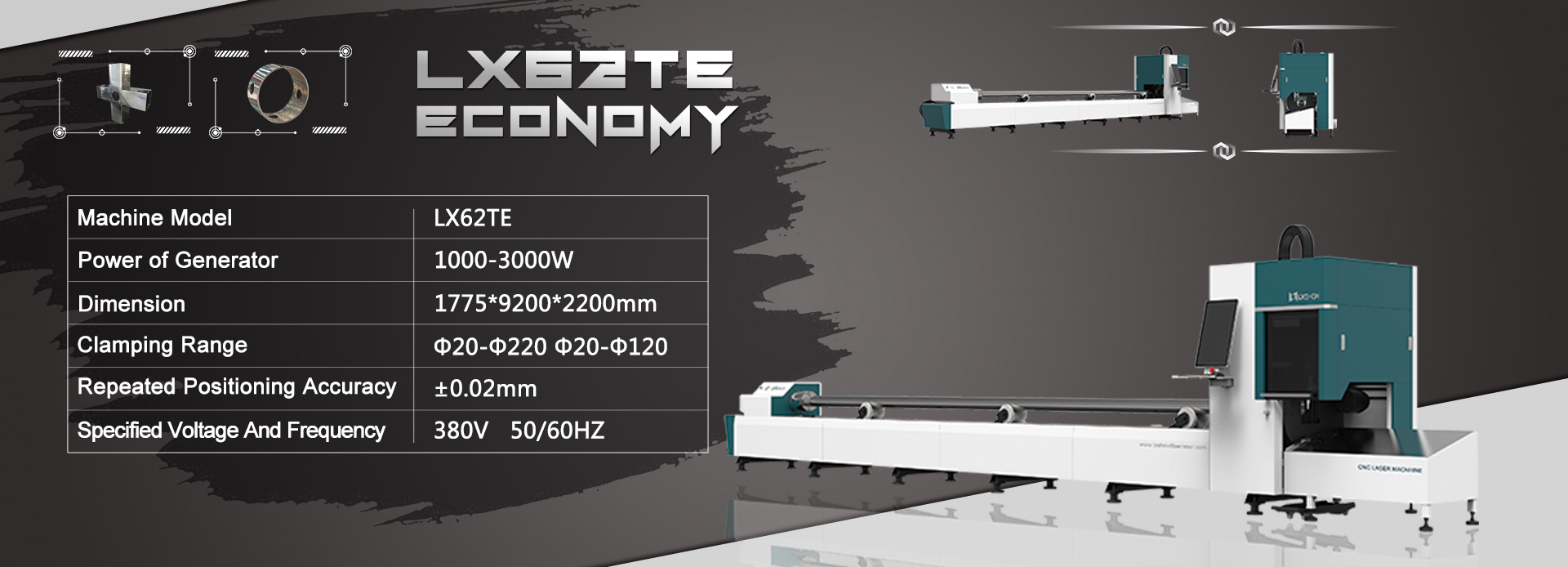

| Machine Model | LX62TE |

| Power of Generator | 1000/1500/2000/3000W(optional) |

| Dimension | 1580*11900*2260mm |

| Clamping Range | Φ20-Φ220mm(if 300/350mm can be customized) |

| Repeated Positioning Accuracy | ±0.02mm |

| Specified Voltage And Frequency | 380V 50/60HZ |

LX62TE 1kw 1.5kw 2kw 3kw CNC OPTICAL METAL SHEET PLATE FIBER LASER CUTTING MACHINE APPLICATION

Application materials: Mainly used for cutting Fiber laser metal cutting machine is suitable for cutting stainless steel, low carbon steel, carbon steel, alloy steel, spring steel, iron, galvanized pipe, aluminum, copper, brass, bronze, titanium and other metals.

Application industry: Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.