A. Double exhaust system to ensure fume extraction effect, matching front and rear chuck, step by step, level processing. The rear chuck equipped with a waste collection system.

B. Follow-up support component system. During the cutting process, it can be ensured that the support frame can always follow the pipe to prevent pipe cutting errors caused by pipe deformation. The front end is equipped with front, rear, left and right dual follow-up modules to ensure cutting accuracy, and automatic tilting and blanking settings to prevent pipe scratches.

C. The machine is equipped with Bochu special chuck, which has better dynamic performance, speed can reach 80r/min, acceleration can reach 1.5G

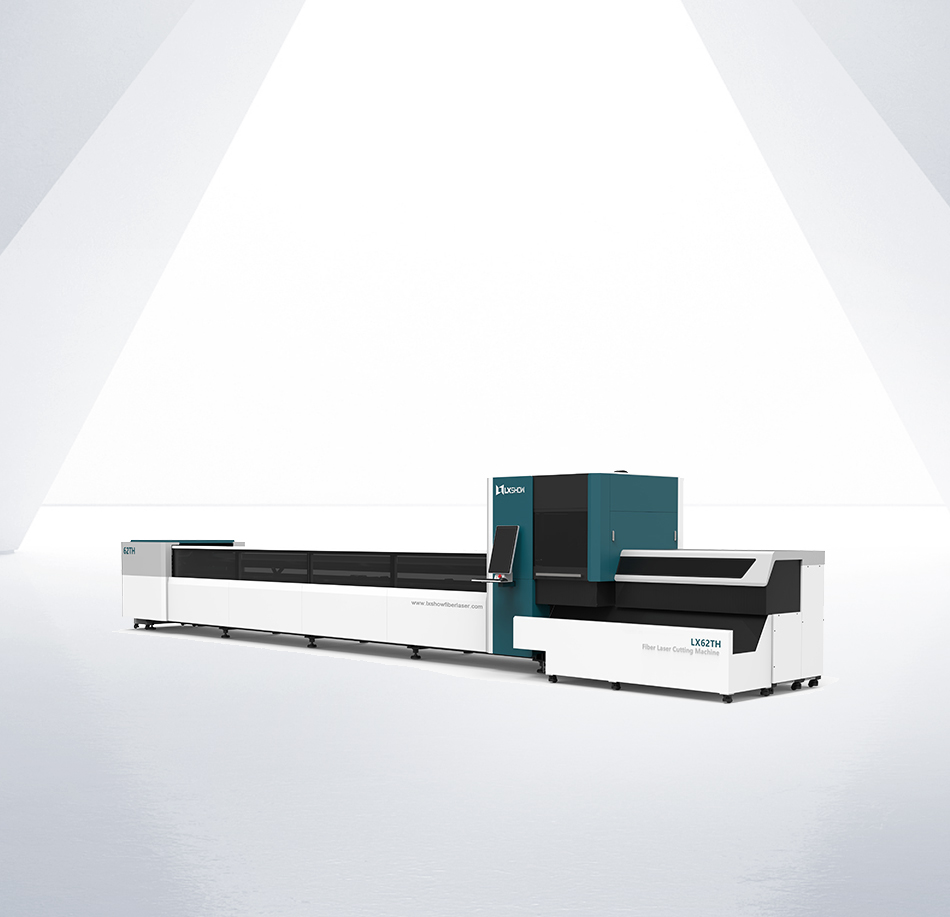

1.Semi-enclosed design, equipped with automatic lifting doors, which is convenient and at the same time guarantees the safety of workers

2.Heavy-duty welded bed, it can meet the high-speed operation of the machine without shaking

3.The front end of the machine is surrounded by design to improve the dust removal effect

THE SEGMENTED RECTANGLE LASER TUBE WELDED BED

Good rigidity, high precision, no deformation during the life cycle; Welded aluminum collet board, formed through high precision process. Good weight and good dynamic performance

PNEUMATIC CHUCK CLAMPING DESIGN

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically.The diagonal adjustable range is 20-220mm(320/350 is optional)

PROFESSIONAL CLAMP DESIGN

Automatic pneumatic chuck, adjustable and stable, clamping range is wider and clamping force is larger. Non - destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering pneumatic chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.

FRACTIONAL AUTOMATIC SUPPORT INSTALLATION

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting

Intelligent Alarm System: It can detect anomalies in advance, reduce hidden dangers, and double the effect of abnormal detection of equipment

Stroke intelligent protection: Detect whole process of cutting head working, quickly feedback the risk and stop it. Double protection with fixed limit to improve equipment and personal safety and reduce risk

THE ABSOLUTE VALUE SERVO MOTOR

System is equipped with servo motor, boot to homework, do not need to return to zero operation, power outages, a key recovery cutting operation.

BOCHU SYSTEM

Easy to operate and easy to learn.

Match 20,000 process data on its graphical programming interface

Built-in nesting software, inventory layout and material utilization are increased by 20% and 9.5% respectively, and the number of spare parts is not limited

Supported languages: English, Russian, Korean, Simplified Chinese, Traditional Chinese

Use the generator of life: The theoretical life of the generator is 10,00000 hours. If the machine works 8 hours a day, it can last about 33 years.

Alternative generator brands: Including the following five brands: JPT/Raycus/IPG/MAX/Nlight

INTELLIGENT AUTOFOCUS

The high efficiency cooling: Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.

Chase the light aperture: Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.

Automatic focus: Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.

High speed cutting: 25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.

Tips:The consumable parts of the fiber laser cutting machine include: cutting nozzle (≥500h), protective lens (≥500h), focusing lens (≥5000h), collimator lens (≥5000h), ceramic body (≥10000h), you are buying the machine You can buy some consumable parts as an option.

TRANSMISSION AND PRECISION

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

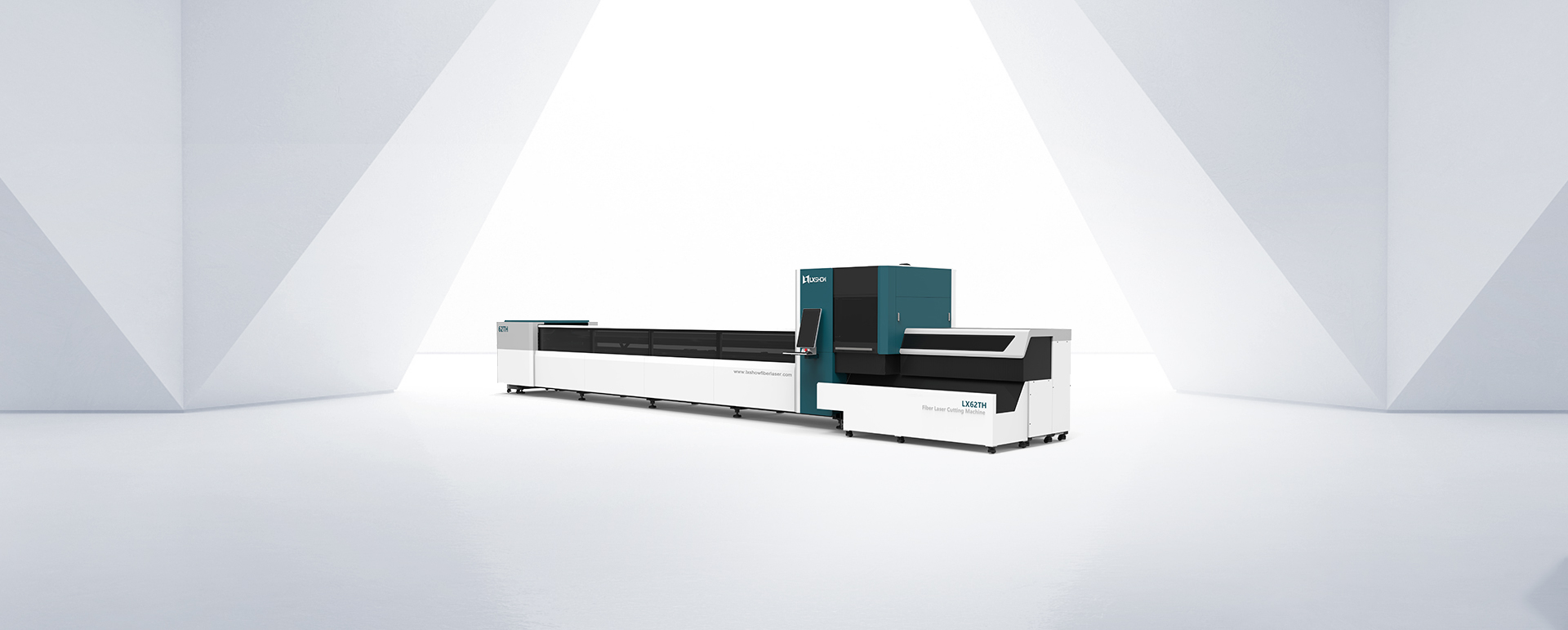

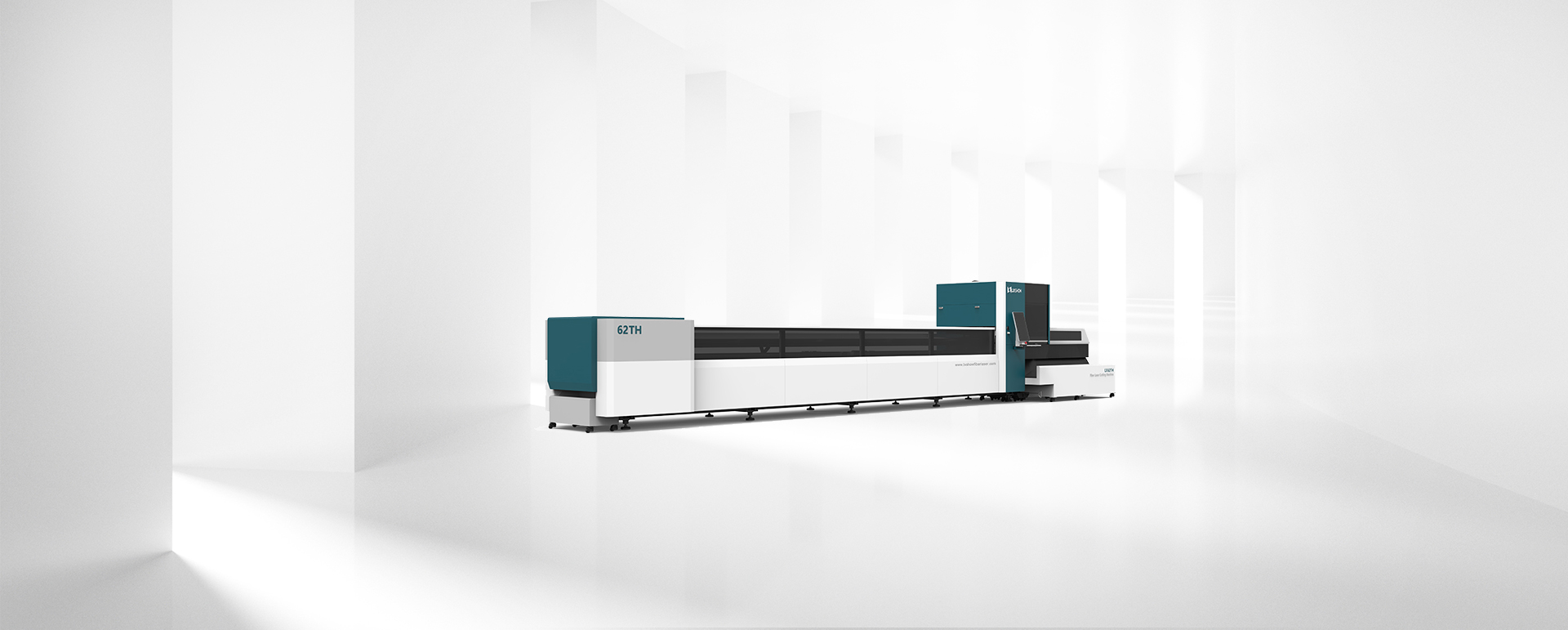

Model Number: LX62TH

Lead time: 10-25 working days

Payment Term: T/T;Alibaba trade assurance;West Union;Payple;L/C.

Machine Size: 9340*1560*1615mm (About)

Machine weight: 8000KG

Brand: LXSHOW

Warranty: 3 years

Shipping: By sea/By land

| Machine Model | LX62TH |

| Power of Generator | 1000/1500/2000/3000/4000/6000/8000W(optional) |

| Dimension | 1580*11900*2260mm |

| Clamping Range | Φ20-Φ220mm(300/350 mm can be customized) |

| Repeated Positioning Accuracy | ±0.02mm |

| Specified Voltage And Frequency | 380V 50/60HZ |

LX62TH 1000W 2000W 3000W

4000W 6000W CNC OPTICAL METAL SHEET PLATE FIBER LASER CUTTING MACHINE APPLICATION

Application materials:

Mainly used for cutting Fiber laser metal cutting machine is suitable for cutting stainless steel, low carbon steel, carbon steel, alloy steel, spring steel, iron, galvanized pipe, aluminum, copper, brass, bronze, titanium and other metals.

Application industry:

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

1.jpg)